Personal Projects

Automatic Plant Waterer:

Design:

After one too many deaths of my plant family, I decided that enough was enough. I brought this problem up to one of my good friends in Physics, and from that point forward we knew that we needed to create a solution!

The Project underwent two main iterations with a budget of $500 sponsored by the NYU prototyping fund.

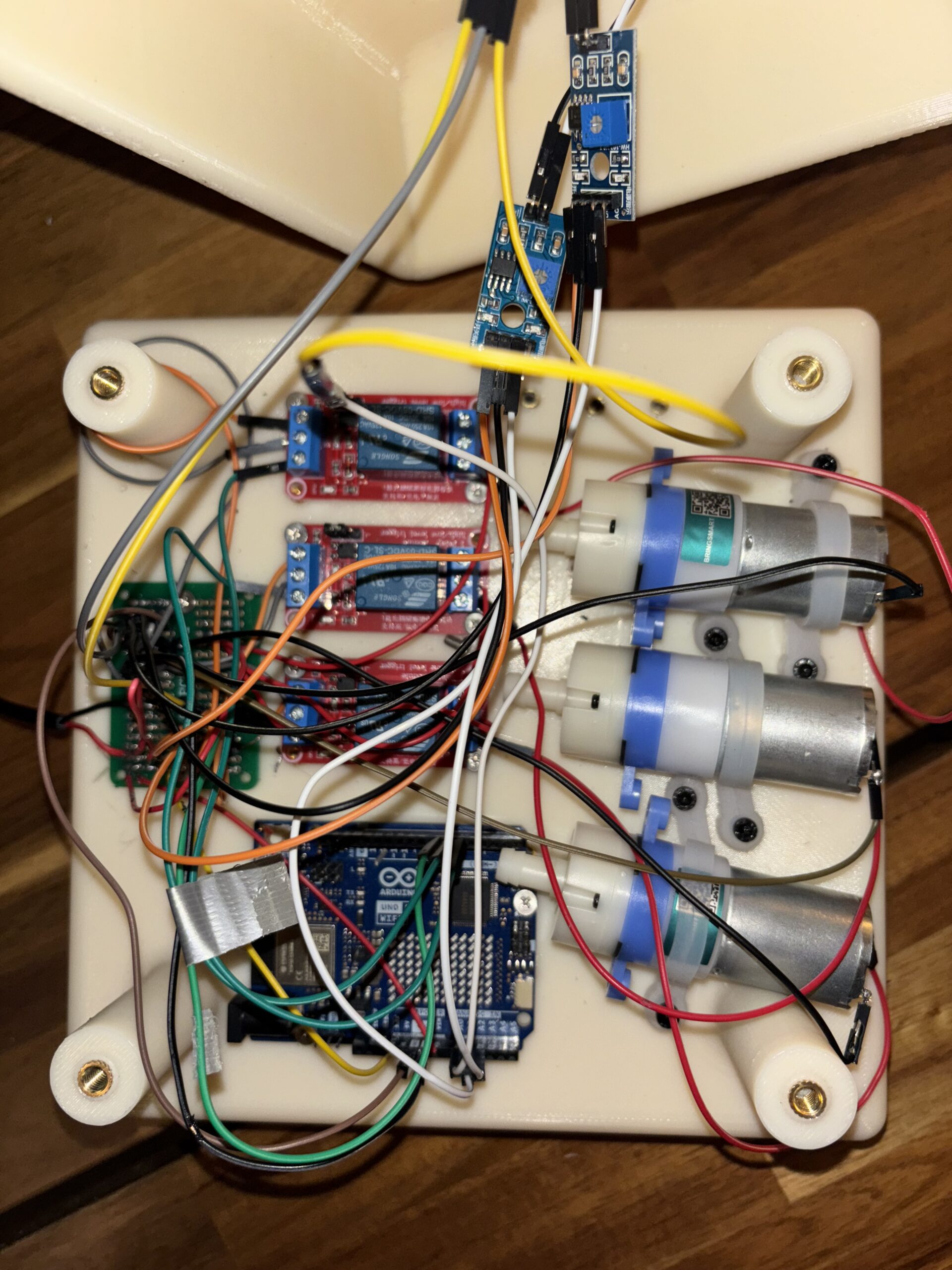

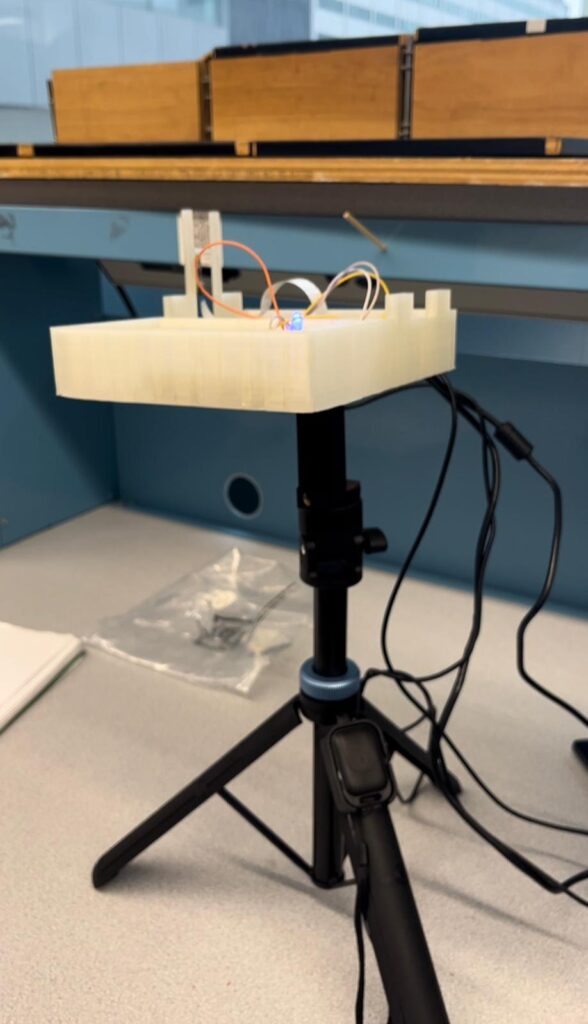

First using a simple base of pine wood, wood screws, and glue, the goal of the first prototype was to get the electronics up and running and have a proof of concept before putting in the effort to improve the aesthetics and design.

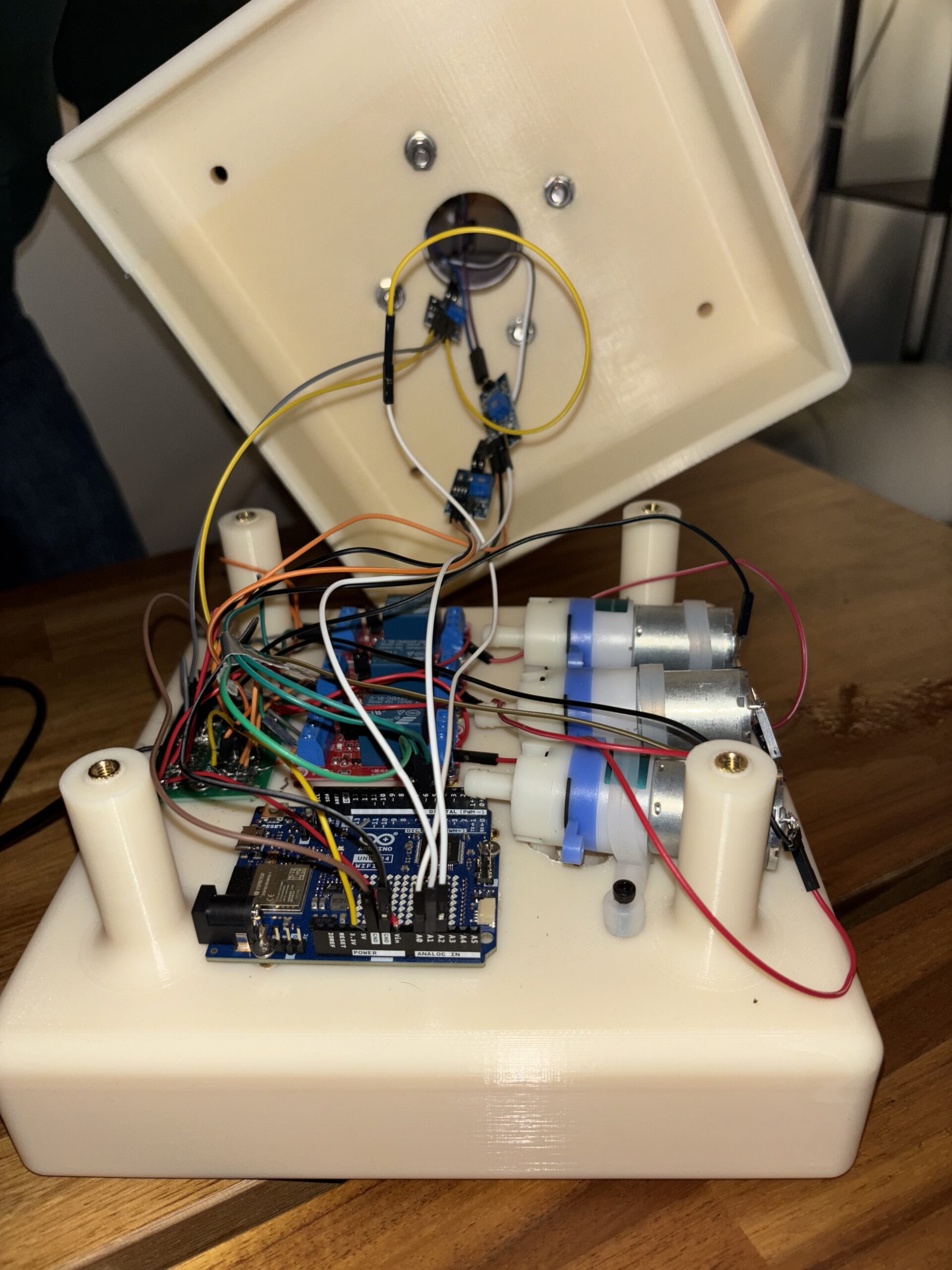

Autowato 1.0 included 3 water pumps and 3 moisture sensors that were controlled by an Arduino Uno using logic from a relay module. The logic and main component across versions 1.0 and 2.0 stayed the same, where the primary change is the use of more permanent wiring with a soldered breadboard.

The Autowato was a very fun learning experience that helped me learn about control systems with the feedback in the moisture sensors, fluid flow calculations when programing how long the device should water your plants for, CAD modeling when designing 3D printable case that kept the electronics secure and could work well with other purchases parts of the frame.

Desk Organizer:

Design:

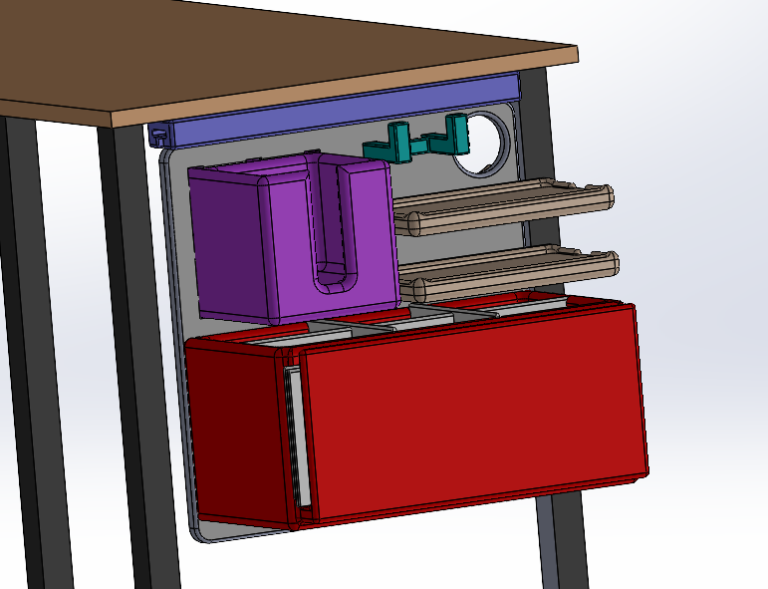

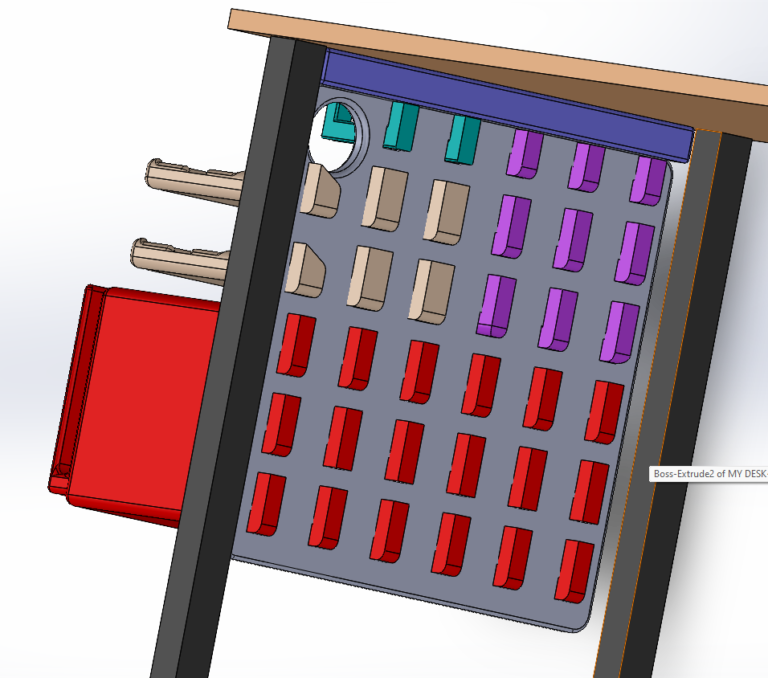

As a student living in a small apartment, I’ve tackled the challenge of maximizing my desk space with a modular desk organizer inspired by the practical and versatile pegboard system.

This project features several key components:

-

Modular Big Bin: This spacious bin helps me store larger items like notebooks and miscellaneous supplies, keeping them organized and within easy reach. Its modular design means I can reposition or expand it as needed.

-

Phone Holder Tray: I created a dedicated space for my phone so I can easily access it while keeping my desk uncluttered. It also has a slot for charging cables, which helps keep everything tidy.

-

Headphone Holder: I needed a solution to keep my headphones from tangling and getting lost. This holder keeps them neatly stored and ready to use whenever I need them.

-

Mug Holder: As a coffee lover, I designed a mug holder to keep my drink close at hand and prevent my desk from becoming overcrowded.

Each element of the organizer is designed to be modular and adaptable, making it a perfect fit for my dynamic needs as a student. This project not only enhances my workspace but also reflects my passion for practical design and problem-solving

Testing:

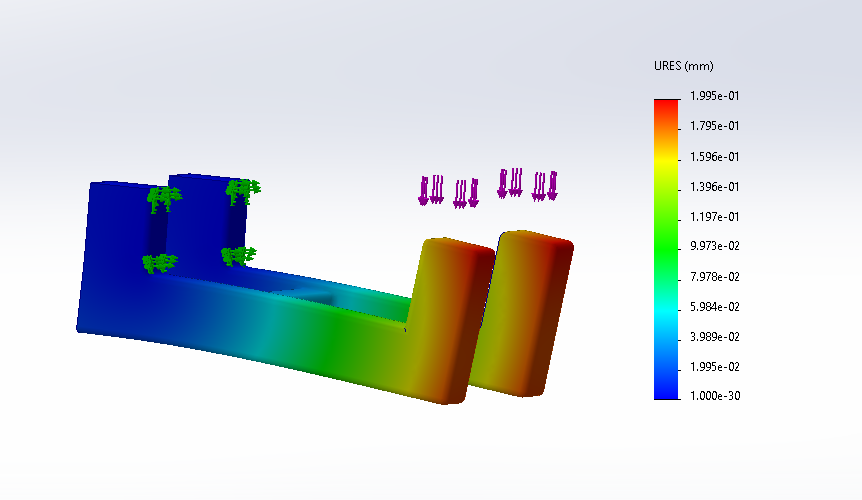

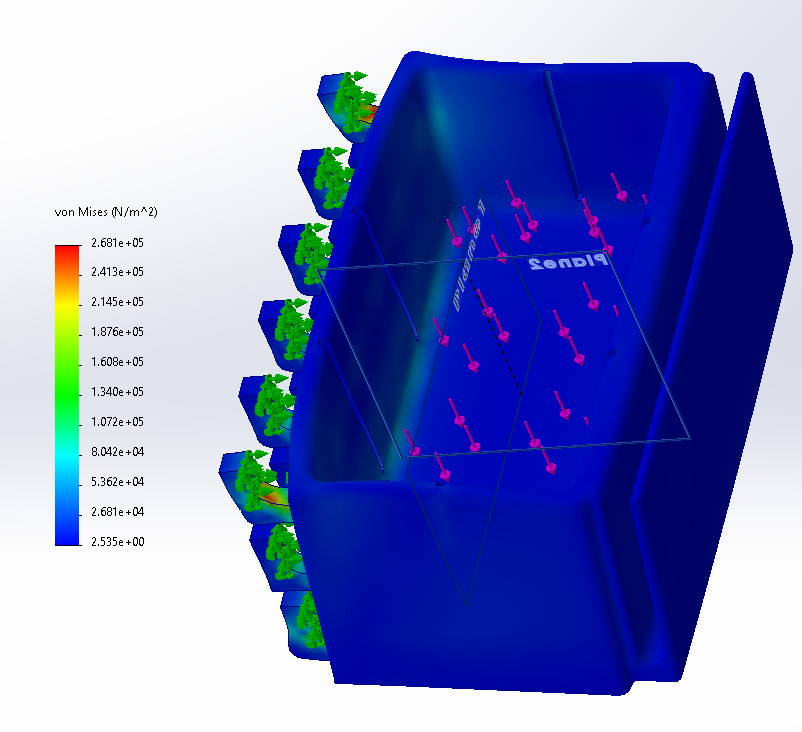

I’ve run SolidWorks simulations for each of the individual parts, assessing both displacement and stress. The maximum displacement observed in each part is 0.2 mm, which should be negligible. Additionally, I used a conservative safety factor of 1.6 in my simulations. Moreover, the maximum von Mises stress simulated was 27 kPa, which is well below the typical yield strength range of 40 MPa to 70 MPa for PLA

Manufacturing:

My original plan for manufacturing was to 3D print everything using the NYU maker space printers.

Since further analysis, I’ve realized that all of the parts not only don’t fit in the NYU 3D printers but would cost significantly more than what I was willing to spend on the project.

To address the issue I plan on reading up on CNC milling to make the peg board main component out of wood and the rest of either 3D printed PLA or laser cut wood.

At this stage, it is necessary for me to reiterate the design process with the new manufacturing methods in mind.

To be continued…

The SquatTD:

Final CAD models:

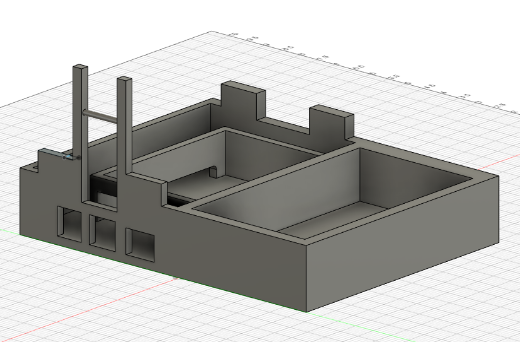

The CAD design above was designed in Fusion 360. The design is used to hold all of the hardware.

Design:

As a student living in a small apartment, I’ve tackled the challenge of maximizing my desk space with a modular desk organizer inspired by the practical and versatile pegboard system.

This project features several key components:

-

Modular Big Bin: This spacious bin helps me store larger items like notebooks and miscellaneous supplies, keeping them organized and within easy reach. Its modular design means I can reposition or expand it as needed.

-

Phone Holder Tray: I created a dedicated space for my phone so I can easily access it while keeping my desk uncluttered. It also has a slot for charging cables, which helps keep everything tidy.

-

Headphone Holder: I needed a solution to keep my headphones from tangling and getting lost. This holder keeps them neatly stored and ready to use whenever I need them.

-

Mug Holder: As a coffee lover, I designed a mug holder to keep my drink close at hand and prevent my desk from becoming overcrowded.

Each element of the organizer is designed to be modular and adaptable, making it a perfect fit for my dynamic needs as a student. This project not only enhances my workspace but also reflects my passion for practical design and problem-solving